Interview: 40 Years of Advancing Pultrusion Technology

The pultrusion industry is the fastest growing sub-sector of the composites industry. This growth is driven by companies wanting improved materials solutions for their customers. With the advancement in technology, fiber-reinforced polymer (FRP) composites products are delivering better durability, performance, and value compared to steel, stainless steel, timber, and other traditional materials.

Dr. Peter Holdsworth (pictured), is the co-founder and Technical Director of Pultron Composites. Peter has worked with FRP composites and the pultrusion process for over 40 years. He explains how the technology has advanced and the importance of the research and innovation at Pultron.

What inspired you to start a pultrusion company?

I studied Electrical Engineering, and part of the course involved lectures in Material Science. I drew a chart measuring Ultimate Tensile Strength against the Modulus of many structural profiles. There was a big gap in the chart where pultrusion belonged. That made me think that there would be a big market for a pultrusion company making products from an insulating material like glass fiber-reinforced polymer that was corrosion-resistant.

Pultron has learned to control the mechanical properties such as creep performance, shear strength and creep-stress fatigue. We can maximize all these properties and customize them for our customers.

When I started looking at pultrusion I didn’t know much about the subject so I read up on it. It was a relatively new technology. I bought some glass and resin, set up a pultrusion machine in the farm workshop, and pulled the resin and glass through the die with a bulldozer. Needless to say, the die seized up so I had to stop quickly, otherwise, the bulldozer would have pulled the workshop down.

When the die was cut open, there was a part of pultruded composite inside. I sent pieces out to a couple of potential customers and they all came back wanting big orders of pultrusion. I set about building the necessary equipment so I could supply composite fence posts.

So that’s where it all started – in 1982, in a farm workshop in Gisborne.

Why are traditional materials being replaced with fiberglass composites?

Pultruded fiberglass composite (GFRP) profiles are engineered materials that can replace steel, stainless steel, aluminum, wood, and other structural materials. In many cases, pultruded composites can offer better performance and value. For example, it can act as an electrical insulator, a heat insulator, and its tensile strength is over 1000MPa (which is more than twice that of mild steel). It has a lower modulus so it can bend and flex more before it breaks.

What is the most exciting research at the moment?

Matrix research. The matrix (resin) binds the fibers together, to transfer load between the fibers for conformity and strength.

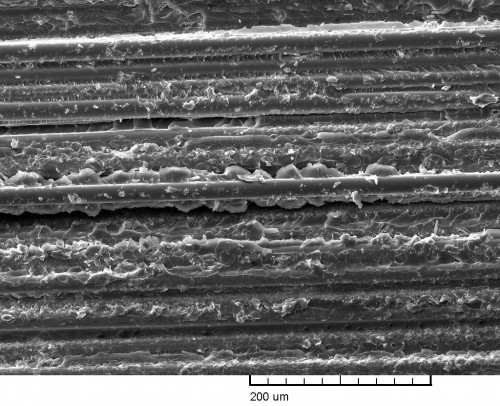

When you bring together hundreds and thousands of glass fibers and bind them with resin in the pultrusion process, the resin needs to fully bind with the glass to create a strong composite.

Image shows longitudinal fiber direction showing good fiber matrix bonding.

The maximization of the binding in the composite is the most important thing in relation to quality and strength.

There is always work to be done on matrix research and we always look for improvements in all our products and processes.

How has pultrusion technology advanced in the last 40 years?

We have invested in research and technology for our products and processes to optimize products. These include:

- increasing production speeds

- customizing material qualities (tensile strength, shear strength, modulus)

- optimizing resin formulations

- developing customized finishing technology.

These have all helped improve performance and quality. By improving processes used to make pultrusion, they are now faster and more efficient to produce. This has led to a reduction in prices over the last few decades making them even more competitive compared to traditional materials.

How does Pultron develop innovative composite components?

GFRP composites already possess a number of desirable properties for engineers. They are corrosion-resistant, non-conductive, and are a quarter the weight of steel.

Pultron has learned to control the mechanical properties such as creep performance, shear strength and creep-stress fatigue. We can maximize all these properties and customize them for our customers.

Through our experience on other projects, we are able to tailor pultrusion profiles. We have a very good understanding of how we can harness the technology to make products suitable for the application.

Today, we are able to produce very high-quality materials for use in all types of applications. These improvements have made pultrusions a much better and most cost-effective material that has opened up new opportunities.

What has driven innovation at Pultron?

Customers and consumer demand have encouraged innovation at Pultron.

The customers we work with have often looked elsewhere to solve their structural problems and when they see what can be done with pultrusion, we work with them to develop a unique product. Engineers have long relied on conventional materials like steel or aluminum but our customers see the commercial value of using a product designed specifically for them.

What are the key benefits of GFRP pultrusion for the mass market?

It is a quarter the weight of steel but still twice as strong. Because the modulus is lower than steel it will contain more energy than steel. They also have high ultimate tensile strength, corrosion resistance, and high absorption of strain energy.

For example, we make pultrusion springs for the world's safest trampoline. The rods hold the energy of the bounce. It will hold 16x as much energy per weight as if you used steel rods. Steel cannot compete in that job because it is 4x heavier. The modulus being a quarter of steel means it can hold 4x the energy – so a 16-fold benefit.

For the mass market, the pultrusion process is ideal for making products. We can monitor what goes into the pultrusion (resin and glass), and we do regular short beam shear tests. If something fails the process is stopped until the problem is investigated and fixed. Testing is done throughout the process to get a consistent product.

What is the future of fiberglass composite innovation at Pultron?

Resin research and further reduction of energy consumption to make pultrusion profiles. As a pultrusion company, it is important for us to keep improving machinery efficiency and speed so we can offer the best value to our customers.

We continue doing matrix research – that never stops. We’re making progress all the time.

About Dr. Peter Holdsworth: Peter is the co-founder of Pultron Composites. In 2017, he was awarded an honorary doctorate in engineering by his alma mater Canterbury University for his outstanding contribution to engineering in New Zealand and internationally.